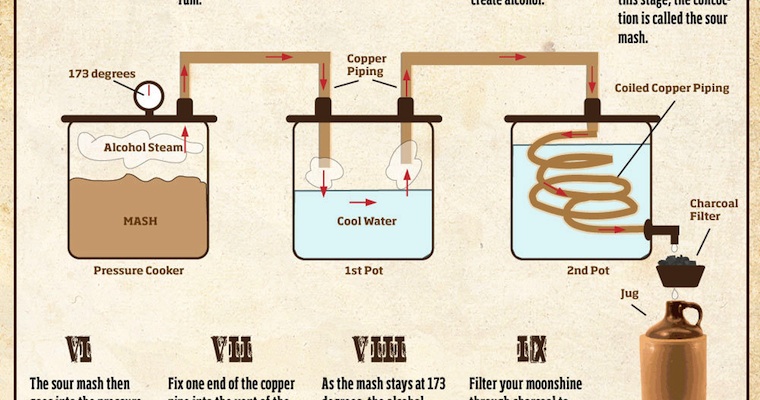

You also run the risk of concentrating fusel alcohols in your sprits. If it starts to rise above 78 oC, the bulk of the water is starting to boil, and the vapours you collect will now be making your spirits weaker. Catch what drips out of the end of the condenser - that is your distilled spirit. When the thermometer reaches this point, and remains steady, it means that the vapours surrounding it, and passing down the condenser is mainly alcohol, with some water. As previously mentioned, ethanol boils at 78 oC. Put your wash in the vat, close it, and gently heat it (over the stove, campfire, whatever - heat is heat). As with the joint at the bottom, this depends on the exact materials you used - it could be as basic as dropping a tin can over the top and epoxying it in place. The top of the column needs capping, with a hole in the cap to allow insertion of the thermometer. Do not worry about removing the weights or blocking the safety-valve, as the still is never under pressure unless you do something stupidly wrong. The gap between the column and the lid can be sealed with solder, epoxy, welded, or sealed with a compression-fitting, depending on the size of the column and the materials involved. The column can be connected to the vat by drilling a suitable-diameter hole in the lid of the pressure-cooker, removing the weight-system. If I was bothered about rust, I could use a similar copper tube and fill it with broken glass. To increase the area inside, I could hammer lots and lots of nails into the pipe, or fill it with steel wool. Looking in my shed, I see a three-foot length of two-inch diameter tube that would be ideal - it's an old bed-leg. If you can increase the surface area within the column, so much the better. A tall column above the vat gives the water vapour a chance to condense and fall back. This means that you will get water vapours in with the alcohol vapours, but they can be reduced. Just remember (again) that, in the majority of countries where you can read this Instructable, you need to check the legality of distilling alcoholic beverages for personal use.Īlcohol and water have surprisingly similar properties - each will dissolve in the other. This is by no means an exhaustive tutorial, so if you are planning to produce quality drinking-spirits on a regular basis (as opposed to something merely flammable), you may even want to invest in a purpose-built still. Since this is more a guide to function than form, you may choose to use different materials to those suggested, such as paying out for all-copper fittings. Before constructing your still, you must check local licensing laws to ensure you are not committing an offence, or obtain a distiller's license. This goes against the usual practice here, but I kind of want to keep my job, and if I did it for real, images posted here can (in a UK court of law) be used as evidence against me. For this reason, my images are a mixture of diagrams and stock photos. Legal point: It is illegal to manufacture spirits in the UK without a distiller's licence which is required under the provisions of section 12 of the Alcoholic Liquor Duties Act 1979 and this includes manufacture for "own/domestic use". You also need a thermometer with a scale that goes to at least +100 oC. I will refer to these parts as the vat, column and condenser. Pure ethanol boils at 78.4 oC, and pure water boils at 100 oC, so heating the wash will make the ethanol boil off first.Ī still has three separate parts - something to heat the liquid, something to help water vapours condense before they escape the apparatus and something to cool and trap the alcoholic vapours. In this case, we're trying to separate ethanol (alcohol) from water. Apparently, the wash has a strength and taste similar to beer, so maybe you would like to start there.ĭistillation is the process of separating a mixture of liquids with different boiling points. You now have a wash that is ready to be distilled. Keep the mixture slightly warm (and sealed from the air) until the yeast has turned the sugar into alcohol. Mix the malted grain with hot water and stir until you get bored - you are dissolving the sugars from the grain into the water. Just as it starts to sprout, quickly kill it by drying. If you don't know about the early stages of whisky distillation, here is a quick round-up: If you want to try distillation without risking breaking the law, then try this project. It's cheaper, easier, and less likely to be illegal in you area. If you are just interested in creating your own alcoholic drinks from scratch, then I recommend starting with brewing beer ( LINK). If you're reading this, I assume you are interested in the theoretical transformation of a relatively weak alcoholic mixture into a relatively strong alcoholic mixture.

0 kommentar(er)

0 kommentar(er)